|

As part of a Natural Gas Pipeline construction, a Natural Gas Compressor Station was installed in a rural community. Soon after the start-up of the Natural Gas Compressor Station the Gas Company received noise complaints from a farm house located approximately 2000 ft to the North-East of the project. After several months of complaining the neighbor finally threatened the Gas Company with a Law Suite. Navcon Engineering was asked by the Manufacture of the Gas Compressor to conduct a site survey to verify the noise situation. The objective of the Phase I Project was: to verify the compliance with the noise regulation to rank the noise emission of all noise sources to develop a 3D noise model to conceptualize noise mitigation measure The Phase II project included the installation of the noise mitigation measures and a post installation noise survey. Navcon Engineering conducted the Phase I noise survey using Acoustic Intensity Technique to isolate the individual noise emission of sources (i.e., Gas Compressor Building, Scrubber, Valves, Oil Cooler, etc.). A 3D SoundPLAN Noise Model was developed based upon the measurement data and site / design drawings. The noise source contribution were ranked to develop the most cost effective noise control measures. A total of 6 noise mitigation scenarios were developed to reduce the noise impact by 5 dB, 8 dB, 10 dB & 15 dB. The noise mitigation scenario with an estimated 8 dB reduction was implemented. The principal noise mitigation measures included the lagging of pipes and valves. The results of the post measurements survey conducted during the Phase II project showed a good correlation with the predicted noise levels (+/- 1 dBA). |

|

Natural Gas Compressor Station with installed noise control measures (i.e., lagged pipes and lagged valves) |

|

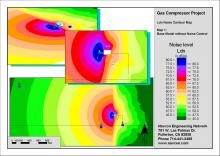

Noise Contour Map displaying the averaged noise impact from the compressor station with noise control. |

|

|