|

Automotive Idle Noise & Vibration Problem Navcon Engineering has provided consulting services for numerous auto manufacturers including Ford, General Motors, Hyundai, Isuzu, Infinity, Mazda and Subaru. Services have included idle noise and vibration, steering wheel shimmy and shake, freeway hop, floor vibration, body flex, wind noise, wind leak, exhaust system & turbo noise, competitive road tests and chassis stiffness evaluations. This case study involved an engine idle noise and vibration problem. Just prior to its introduction into the US market, the manufacturer's customer evaluation survey indicted that the steering wheel shake and interior noise level (95 dBL) were unacceptable. The vehicle manufacture asked Navcon Engineering to Diagnose the Problem and to develop Prototype Fixes. The project included the following principal tasks:

Using the test data and the Impedance Model results, Navcon designed, fabricated and verified the noise and vibration mitigation measures. The structural modifications included modifying the radiator mounts, stiffening the steering shaft cross bar steering wheel and A-Pillar. The idle noise was reduced by 15 dB, the steering wheel shake dropped by more than 20 dB. |

|

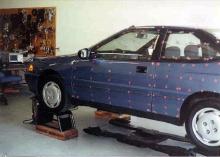

The "red dots" show the measurement locations for both the modal test and the operational deflection shape test. The modal survey was conducted using a SIMO testing method. The vehicle was excited with an APS Dynamics long stroke electro-dynamic shaker. The test system included a multi-channel HP analyzer, PCB instrumentation and Vibrant Technology modal software. The operational deflection shape survey was conducted with the engine running at idle, the transmission in "Drive" and the brakes locked. |

|

The idle noise was caused by a vehicle body oil can / front end bending mode excited at the engine firing frequency. Due to the interior trim panels, no modifications could be made to the B-Pillar. The A-Pillar stiffener shown in the photo reduced the interior noise level by 20 dB. |

|

|